Here we sit on a rapidly changing planet. It’s no longer simply trendy to be eco-friendly, it’s imperative. We owe it to our children, and their children, to live by sustainable principles now. At Brandstand we place a great deal of importance on the sustainability of the products and processes we use and sell. We feel it’s up to every business and individual to take responsibility for being environmentally friendly. We’re delighted that so many of our clients are starting conversations with us about the sustainable nature of our solutions. They require it, their customers require it and frankly, our planet requires it.

Here’s how we deliver our eco-friendlier solution.

Eco-Friendly Fabric

In the old days, many exhibition and display solutions were constructed using Aluminium Composite Material (ACM), packed full of Polyethylene. It was a great product in that it was hard-wearing and lasted years, but it was terrible for being heavy to use and very environmentally unfriendly. Around 70% of all our exhibition and conference solutions now utilise fabric rather than ACM as the main display material. There are a few reasons this makes more sustainable sense.

Reduced Carbon Footprint

Due to it’s lightweight and the ability to fold into a small package, fabric prints are considerably more energy-efficient when transported than the heavy traditional banner vinyl – which often needs to be packaged in high volume tubes. Your organisation’s “Carbon Footprint” can, therefore, be significantly reduced – particularly when sending a replacement or interchangeable graphics to multiple locations.

Fabrics “compactness” also means it takes up very little storage space, meaning less heating and lighting requirements etc.

Fabrics are so easily produced that many clients find they keep their framing for a long period of time and then simply wash and re-use their fabric displays.

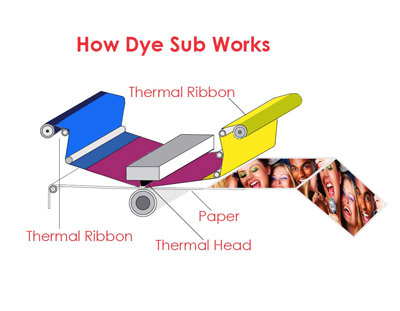

Dye Sublimation – A More Sustainable Printing Process

Sublimation is when a substance transitions between the solid and gas states without going through a liquid stage; the action of dry ice exposed to room temperature is a common example. In a Dye-Sublimation printer the water-based printing dye is heated up until it turns into a gas, at which point it diffuses onto the printing media (in our case the Fabric) and solidifies. The result is a far more eco-friendly, vibrant, long life and colourfast image.

This is how it works

The Environmental Advantages of Dye Sublimation Printing on to Fabric:

- Reduced Water Use

- As the solid turns straight into a gas without going through the liquid phase, Dye-Sublimation is a completely waterless printing process. For this same reason, the whole printing cycle is extremely clean; there are no liquid inks to clean up and no print heads to get clogged. This significantly reduces the amount of wastewater going into the environment.

- Dye sublimation offers other advantages over wide-format inkjet printing – which is traditionally used in the Display Industry. As no water is used in the process the prints are dry and ready to handle as soon as they exit the printer. Often ink-jet printers use energy soaking heaters to dry their prints when quick turnarounds are required.

- Water-based inks – No VOC’s! (Volatile Organic Compounds)

- Volatile organic compounds (VOC’s) are organic chemical compounds that have high enough vapour pressures under normal conditions to significantly vaporise and enter the atmosphere. A wide range of carbon-based molecules, such as aldehydes, ketones, and other light hydrocarbons are VOC’s

- The inks used in Dye-Sublimation printing are water-based therefore they don’t produce the Volatile Organic Compounds associated with Solvent based inks.

Recyclable Aluminium

As well as being lightweight and strong, the Aluminium extrusions and framing used in our display hardware are recyclable.

This might not seem that important, but take a look at the facts. The recycling process involves simply re-melting the metal, which is far less expensive and less energy-intensive than creating new aluminium which must first be mined from bauxite ore and then refined using significant amounts of energy. Recycling scrap aluminium requires only 5% of the energy used to make new aluminium.

Unlike many other materials when recycled, Aluminium loses none of its structural integrity and is therefore infinitely recyclable.

Aluminium Framing is used in our display hardware

Fluted Polypropylene

Fluted polypropylene, or CorFlute as it is sometimes called, is a lightweight, cost-effective and environmentally friendly alternative to wooden, cardboard or solid plastic sheets. It is waterproof, damp proof and scratch-resistant while maintaining a flexibility that allows it to be cut, shaped, scored, glued and welded. The fluted polypropylene that we stock is also approved for use in contact with food products. It is an excellent substrate for signage and panelling, both indoors and outdoors, but also makes a great structural solution when configured correctly.

Our fluted polypropylene is produced from 100% co-polymer and is recyclable, making it a more environmentally friendly solution compared to wooden or cardboard packaging.

We take an active role in managing our waste ensuring that we place as much as we can for recycling. Our pallets are all collected on a weekly basis and either re-used or re-purposed. We re-purpose our polypropylene offcuts where possible to minimise wastage and ensure that any additional scrap pieces go to commercial recycling.